Thank you for your interest in OCO Labs.

If you need help with questions or spare parts now, please contact info@ocolabs.com

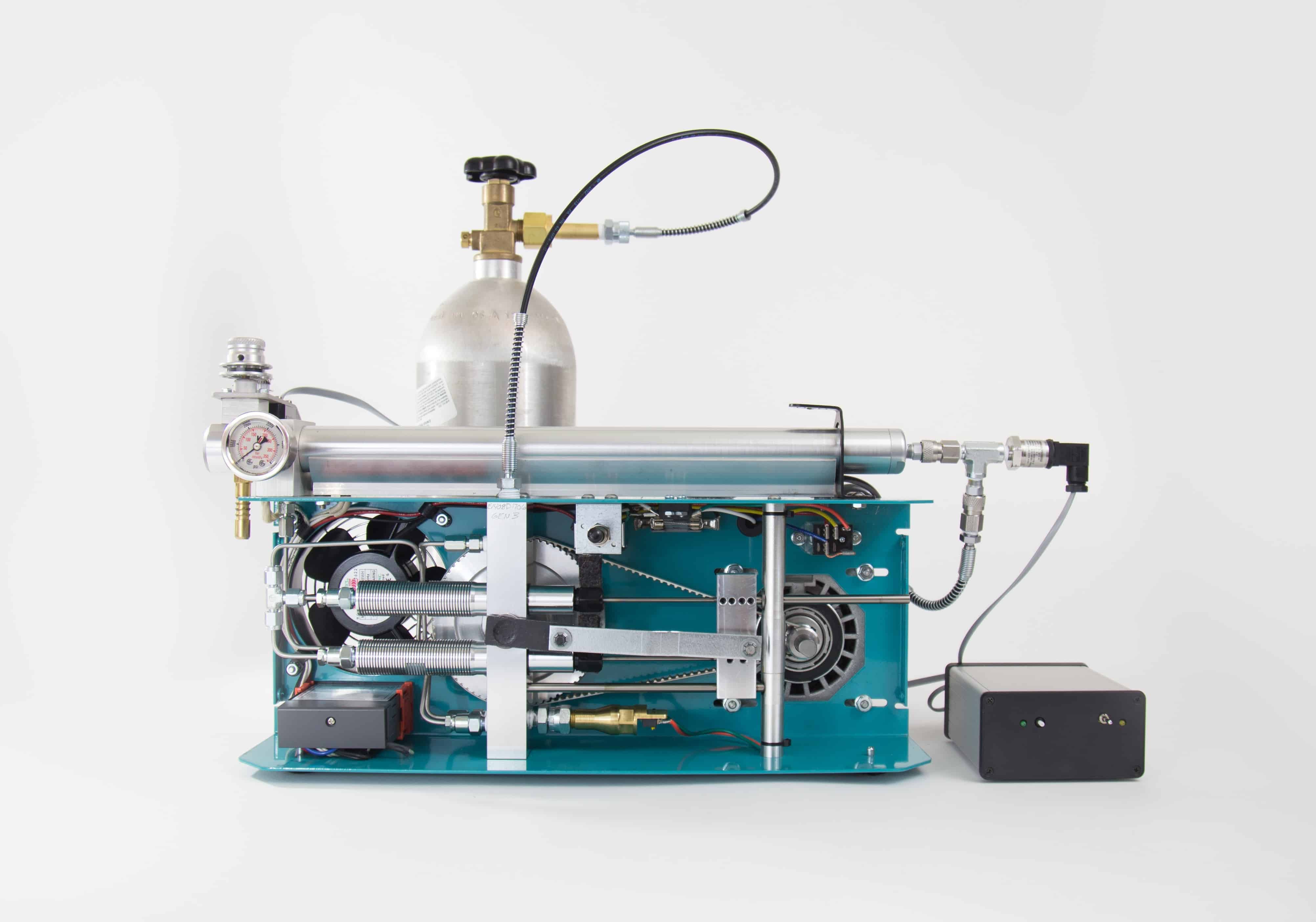

The SuperC Extraction System

SuperC Specs

Price: $4400 (AutoPilot included)

Capacity: one ounce

Unit Size: 18 7/8”W x 12 1/2”D x 12 3/4”H, weight: 37lbs

Motor: ½ hp, 120 volts ac, 8.5 amps, 1725 RPM’s, 1000 watts, continuous duty

Collection Vessel: 1 L media bottle

Pressure Range: 800-4500 psi

Temperature Display: Independent LED display

Temperature Control: ambient–90 degrees C

Run-time: 60-90 minutes (for most extraction applications)

Expansion Rack Specs

Price: $2750 for Expansion Kit

Capacity: Four ounces

Unit Size: 11.5" W x 5.5" D x 47.5" H, weight: 32 lbs

Collection Vessel: 1 L media bottle

Pressure range: 800-4500 psi

Temperature Display: Two independent LED displays, two temperature zones

Temperature control: ambient-90 C

Run-time: 6-8 hours (minimum)

The SuperC™ Extractor

The basic SuperC™ is the core of our expandable product line. It is a quality engineered, entry level supercritical fluid extractor (SFE). It offers many of the features typical of commercial SFE equipment, but at a more affordable price. With a one ounce capacity and automatic valve, the basic SuperC is perfect for home extraction, batch testing, and research and development.

With 90 minute runtimes, the SuperC™ allows you to extract essential oils on your own terms. Independent pressure and temperature controls let you dial in the ideal extraction for your material. The extractor is designed to be maintained and serviced by the user, removing the tricky mechanical learning curve of the larger systems. It’s simple to use, safe, convenient, and easy to clean. Since it only requires one standard 110V outlet, the SuperC™ can be used most anywhere. 220V models are also available for our international customers (contact us for more info).

If your needs exceed the one ounce capacity, you can expand your SuperC™. The Expansion Rack for the SuperC™ increases per-run capacity from one ounce to four ounces. This solution allows existing users to upgrade their SuperC™ without replacing the entire system. This modular expansion is a great solution for the small batch or boutique production of essential oils.

The Rack is offered as a special order product, and all Rack sales are final. For this reason, we recommend the purchase of a basic SuperC first, so that you can have a couple of successful runs and be sure it will meet your needs. All of OCO Labs' upgrades will retrofit to the base model SuperC™, so you will never need to buy a new system if you choose to upgrade in the future.

SuperC Process

SuperC Product Profile

Supercritical Fluid Extraction: a Primer

Supercritical CO2 has so many advantages that it is now used world wide to extract compounds from a huge variety of materials. Well known applications are the extraction of caffeine from coffee and tea. Other less known applications use CO2 superfluid extraction (SFE) to extract vitamin E and tocopherols. Unlike other extraction methods, CO2 is tunable to focus the extraction on particular compounds. CO2 above 87.98 degrees Fahrenheit (31.1 C) and 1071 psi is considered supercritical. Supercritical CO2 is widely used as a solvent because increasing the pressure and temperature of supercritical CO2 changes the density, surface tension, and viscosity of the CO2. Light fractions such as terpenes (responsible for flavor and aroma) start coming over at lower pressures and temperatures. They begin easily dissolving at around 1500 psi and 110 F. The larger more active oils start to come over at higher pressures and temperatures, above 2500 psi and 120 F. Successful CO2 extraction is more than just getting the extraction device. It requires an appropriate recipe of temperatures and pressures to focus on your desired oils. Virtually all commercial plant species have been studied under supercritical CO2 extraction, and there are many papers published with this information. The focus of practically every paper is to determine the best temperature and pressure profile to maximize extraction efficiency. Google scholar is a great place to start in researching for your own application.

FAQ

Q: What do I need to get started?

A: In addition to the SuperC, you will need a non-dip tube CO2 tank. You will also need to purchase a lubricant. We recommend liquid-at-room tempaerature coconut oil.

Q: How long does it take?

A: Most extractions take about an hour and a half per ounce.

Q: Where do you get CO2?

A: CO2 is available in most towns. It is used with soda dispensers and beer taps world wide. Ask the local restaurant where they get theirs. Welding supply yards are also a common source of CO2, though you should take care to use clean tanks filled from a clean source. Debris from dirty tanks can cause o-rings to fail.

Q: What is the cost per run for CO2?

A: A one hour extraction uses about 2 lbs of liquid CO2, and many places sell the gas for about $2 a pound.

Q: What percentage of extract can I expect?

A: This will vary depending on your source material and application. In some cases CO2 will extract less total oil as a percentage than other solvents. Most material with a high oil or resin content will produce a 15% return or greater.

Q: What do I need to do to treat the extract afterwards?

A: In most cases nothing at all. Some secondary processing may be desired depending on the final product you desire. If you wish to remove any waxes, an ethanol winterization may be necessary. Others may remove bound water using a vacuum chamber.

Q: How long has the extractor been on the market, is it tested?

A: Available since April of 2014, there are over 400 SuperC extractors in 10 countries.

Q: What if I want to extract oils for foods etc?

A: The SuperC uses stainless steel, aluminum, steel and a small amount of delrin plastic in its construction. There is nothing in the unit which is inherently poisonous, but all products produced by the extractor should be lab tested for quality to ensure safety.

Q: Does the SuperC require maintenance?

A: Yes. Regular maintenance is performed by the user. In addition to regular lubrication, eventually the o-rings need to be replaced. Videos showing how this is done can be found on our Support page.

Q: Do you have a dealer program?

A: Yes. Email us to see if you qualify.

Q: How do I get information on how to extract oil from my particular plant species?

A: Google scholar accesses most of the scientific literature. A search of your plant species along with "supercritical CO2" or "superfluid extraction" will usually bring up many papers on almost all plant species. Most of these publications include the best temperature and pressure settings to extract a given oil.

Q: Can I just turn it on and run it?

A: Yes and no. You need to understand what temperature and pressure is right for the oil you want to extract. Terpenes are more soluble around 1500 psi and 115 F, the heavier, more active oils dissolve best around 2800 psi and 130 F. There is a dead zone from approximately 2000-2200 psi where you will get very low returns. Avoid running in this zone. Experimenting with these values as your starting point will help to get your preferred extraction profile.

Download the SuperC User Manual

Return Policy

All sales are final. Any issues with orders must be brought to our attention via email within 5 days of receiving your shipment.

Questions?

The OCO Labs Customer Service Team is ready to help!

Email us at info@ocolabs.com